By ANN GREEN

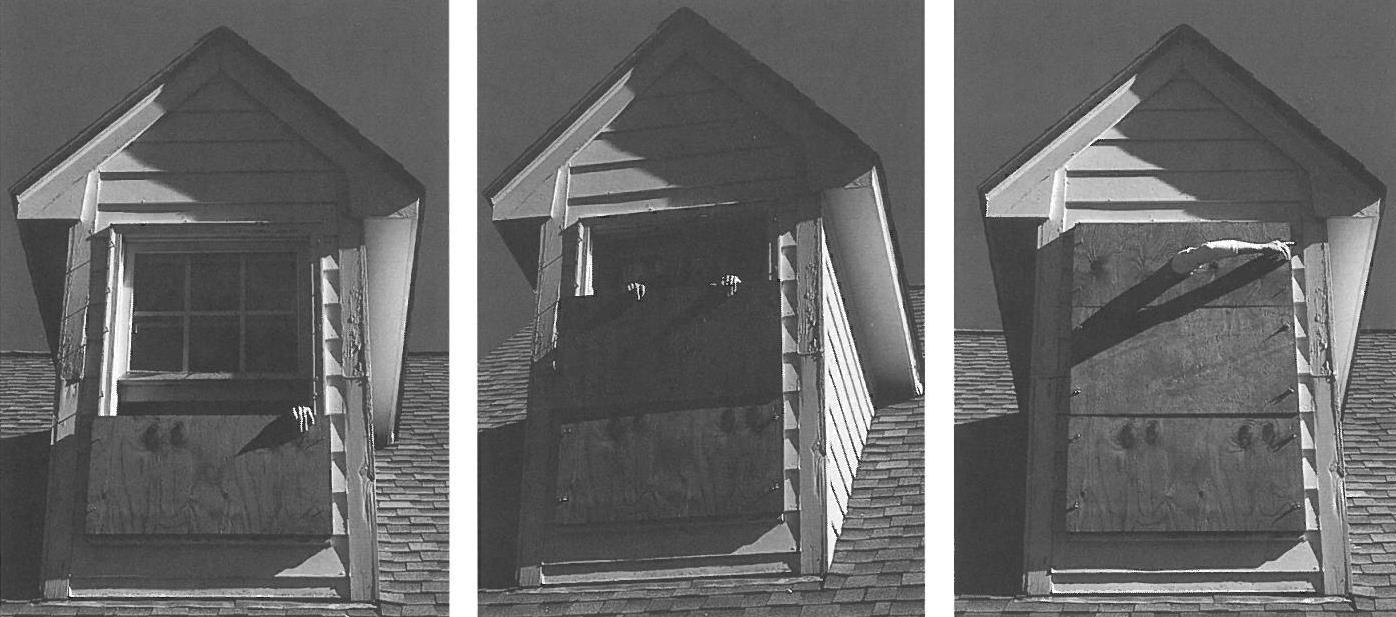

After prefitting, plywood shutters can be installed from the inside of a home. Photos by Scott D. Taylor.

When the next warning goes out for a hurricane in Wilmington, Spencer Rogers won’t have to worry about boarding up his windows.

His new plywood storm shutters will keep flying debris from shattering his windows — and the shutters are easy to install.

“Plywood storm shutters that protect windows during hurricanes have been in use for many years and are one of the most cost-effective ways to build shutters,” says Rogers, North Carolina Sea Grant’s coastal construction and erosion specialist.

“Storm shutters may not be the highest priority for hurricane retrofitting. But as the wind-resistance of a building is improved, shutters become a top priority in high-wind zones. For some homes, threatening sources of debris may make shutters the first priority.”

Rogers says shutters prevent wind-blown rain from going through a broken window.

They also prevent the “increased internal pressure on the building that results from any large opening, such as a broken window on an upwind wall,” he adds.

Rogers worked with South Carolina Sea Grant, Clemson University and Blue Sky Foundation in Raleigh to test the new shutter design.

Rogers’ shutters are a prototype of a design that, after prefitting, can be installed from the inside of the home without a ladder — even on a second story.

For easier installation before a storm hits, Rogers recommends precutting the panels to size, attaching permanent fasteners on the house and storing the panels.

Even if the plywood shutters are preinstalled, it can be hard work to put them in before the storm, says Rogers. “It is particularly difficult when a ladder is needed for installation,” he adds. “Gusty winds and heavy rains can make ladder work even more dangerous.”

Plywood shutters, which are relatively inexpensive and easy to construct, aren’t the only type of retrofitting that Rogers has done at his home.

Over the years, he has elevated water pumps and other equipment under the house as high as possible and dismantled wiring in a low-elevation room. To better connect the roof to walls, he installed better wind-resistant asphalt shingles and hurricane clips.

Rogers says dismantling the room under his house, which is still used for storage, has prevented extensive flooding. “In our recent binge of hurricanes, the room has been flooded three times. It has required nothing more than a cleanup with a broom and hose,” he adds.

More recently, Rogers built a strong room — a small interior room offering protection from high hurricane-force winds — on the main floor of his home. The room is a rebuilt closet under the stairs in the center of the house. Rogers added three layers of plywood to the walls and ceiling and two layers to the door. He also reinforced the door hinges and latches.

“During the worst winds of the five most recent hurricanes that hit Wilmington, my family huddled in a central hallway of my home,” says Rogers. “Although I never felt that our lives were threatened or that we should have evacuated to another building, it became apparent that the added assurance of a strong room would add peace of mind should we get hit again.”

Wilmington’s wind risk from hurricanes is significantly lower than the extreme tornado winds — more than 200 mph — used for national “safe” standards. Thus, Rogers chose a strong room design developed and tested at Clemson. The room has an estimated capacity of about 60 percent of the national standard for safe rooms designed for the worst tornados.

Rogers emphasizes that no single technique is right for making everyone’s home safer during a hurricane.

“The hurricane resistance of many homes can be substantially improved using a variety of techniques to reduce the chance of structural damage and damage from wind-blown water or flood water,” says Rogers. “Each house is different. What matters is finding the weakest components and looking for the most cost-effective priorities for each house.”

The best — and least expensive — way to make a building storm-resistant is to modify it while it is under construction, says Rogers.

“It is much easier and more reliable to do a brand new house if you want a higher standard for wind resistance than retrofitting an old house,” he says.

Wind-Resistant Materials

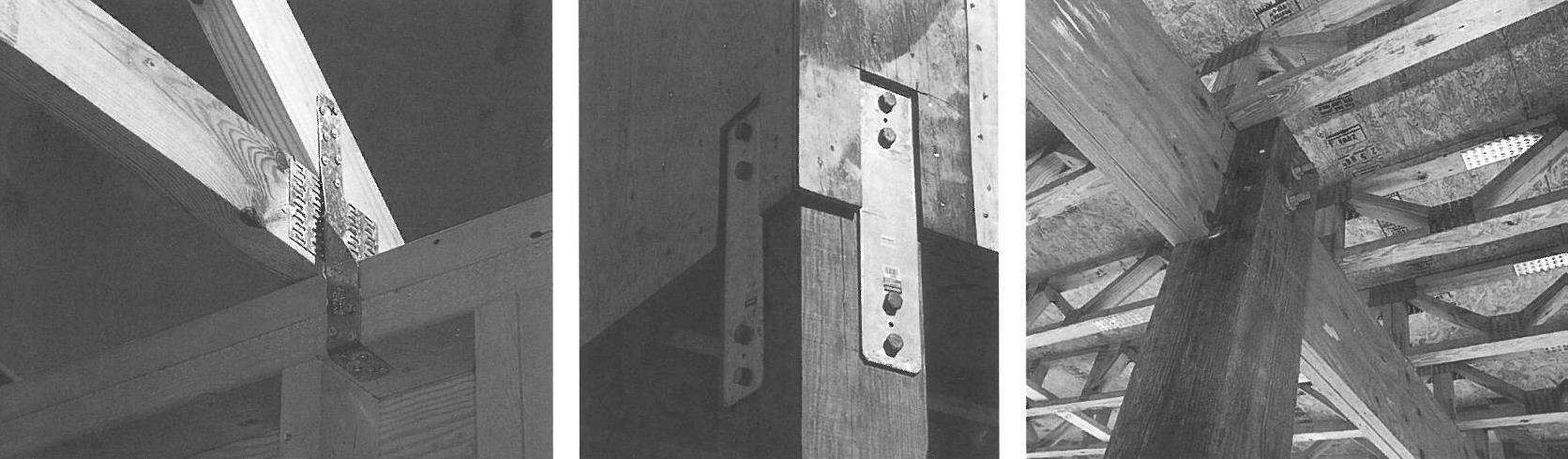

Hurricane clips or metal straps help strengthen the connections between the wall and roof in new or existing homes. Photos by Scott D. Taylor.

Decades of experience support Rogers’ advice. Over the last 27 years, he’s surveyed the structural damage from major hurricanes that have hit the East and Gulf coasts.

He says the key to preventing structural wind damage from hurricanes is connections.

To prevent structural damage, strengthen each separate connection between the top of the roof and the foundation. It is critical to prevent water from penetrating through exterior siding, roof coverings, wall sheathing, windows, vents and doors.

“It is not the board that breaks in a hurricane,” says Rogers. “It’s what holds the boards together — usually a nail or a screw. It’s critically important that everything be strongly tied together.”

Likewise, buildings don’t simply blow over in the wind, he says. Inadequate connections and the wind’s forces of uplift often cause the damage.

Wind-uplift forces cause airplanes to fly, and the same principle applies to roofs. When a high-speed wind blows across a low- to moderately sloped roof, it creates a lift. The roof pulls off when the lift force exceeds the roof’s weight plus the capacity of its connections to the walls. Without the roof, the walls collapse.

Homeowners can counter the problem by working from the top down, making sure the roofing is well-attached to the sheathing, the sheathing to the roof framing, framing to the walls, and the walls to the floors — all the way down to the foundation.

Rogers advises using metal straps or hurricane clips rather than nails alone to secure the roof.

“Straps change the direction that nails are pulled and make any nail used 10 times stronger than typical toenailing,” he says. “You also need to make sure each connection is tied to something lower. The higher the elevation of the connection in the building generally, the more important it becomes. The lower you go in the building with the connections, the heavier the sum of the parts for the connection.”

One way to strengthen connections between the wall and roof in existing homes is to use a retrofit bracket developed by Clemson researchers Tim Reinhold and Ed Sutt.

The structural bracket can be installed from the inside of the room without removing sheetrock. Once installed, the system is hidden by molding.

To install the roof on a new 2,400-square foot home at Carolina Beach, builder Michael Hogan glued down the roof, screwed it, and then used self-adhering tape on the roof deck seams for a secondary water barrier.

“It cost about $500 extra to do this,” says Hogan. “It makes the roof a lot stronger.”

Below the roof, windows and doors are also important to maintaining the integrity of the building envelope — they need to be strong and well attached. French and sliding-glass doors — with wide spans and poor connections in the middle — can be vulnerable to strong wind. And large picture windows are often not strong enough to survive fierce storms.

Another troublesome spot is the garage.

It is important to use garage doors with extra bracing and heavier tracks designed for high wind resistance. “The garage is one of the weakest points in the house for lateral wind forces,” says Rogers. “The consequences of a door failure can be even more of a structural threat than a loss of a window elsewhere in the house.”

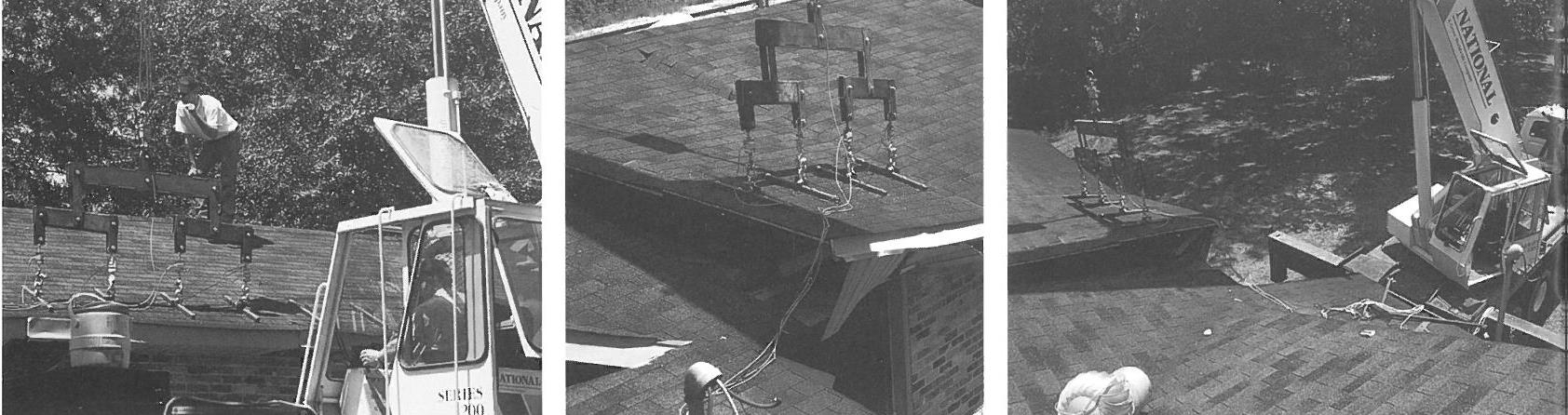

Last summer, Clemson researchers used everything from high-tech crowbars to a huge crane to “test to destruction” houses that were outfitted with hurricane-resistant retrofits. They first tested houses as they were built without any hurricane-resistant features and then retrofitted the houses with hurricane-resistant features.

The homes in Horry County, S.C., all had been damaged by floods in Hurricane Floyd and were slated for destruction. South Carolina and North Carolina Sea Grant programs were involved in the project.

Retrofits for connecting the sheathing to the roof framing made a “significant improvement in the roof connection uplift performance,” says Reinhold.

However, there were a few surprises. In two cases, the rafters split before the roof connection failed, according to a report. “This is an indicator that building code standards have been improving, with lessons learned from building performance in previous storms,” he adds.

The researchers also tested the homes’ resistance to flying debris by shooting wooden two-by-fours from an air cannon.

Flood Damage

Clemson University researchers used a huge crane and other equipment to “test to destruction” a Horry County, S.C., home that was flood-damaged by Hurricane Floyd. Photos by Spencer Rogers.

Buildings most often are destroyed by waves and erosion that accompany storm-induced floods. Erosion causes structures to collapse, and the power of even small waves can pound a home into pieces. Research has shown that a 1.5-foot or higher breaking wave can easily destroy a well-built house designed for 120-mph winds, Rogers says.

The remedies are an open piling foundation and a high floor elevation. Piling foundations on oceanfront homes must extend to at least 5 feet below sea level so that waves can go through them unimpeded.

North Carolina has the second-oldest hurricane construction codes in the country, first implemented in the 1960s and improved over time.

The first test of the latest foundation standards came with Hurricane Fran in 1996, which brought storm surges up to 11 feet and coastal winds of more than 100 mph.

Of the 205 new Topsail Island structures built after the piling foundation standards set in 1986, 200 buildings survived — while 180 oceanfront buildings on the island that were built on shallower pilings were destroyed by erosion, Rogers notes. It is suspected that the five newer buildings lost were not in compliance with the 1986 code.

At Carolina Beach, oceanfront structures are required to have 26-foot pilings — 16 feet in the ground and 10 feet out of the ground. Waterfront structures require 20-foot pilings — 10 feet in the ground and 10 feet out of the ground.

To go beyond code and make a stronger foundation, Hogan installed the pilings six feet deeper than required — to 16 feet in the ground — in one waterfront home.

“It costs about $10 a foot for piling installation,” says Hogan.

Existing buildings also can be retrofitted to prevent flood damage. After Hurricane Emily in 1993, more than 50 Outer Banks homeowners raised their houses by 2 to 10 feet, Rogers says. They did this because they’d been flooded as many as three times in the previous 10 years. The costs averaged $11,000 to $15,000 per house.

Most of the expense comes in replacing the foundation and extending connections for sewer and utilities. The higher elevation gives the owner new space under the building for storage or parking.

An option is to move low-elevation utilities such as electrical outlets and switches that would short out and interrupt power to the rest of the house if they were flooded. An electrician can remove them and install them at higher elevations. When equipment or appliances wear out — air conditioners, water heaters and heat pumps — you have an opportunity to raise the elevation to prevent damage, Rogers suggests.

New N.C. Program

In Florida, the Institute for Business & Home Safety (IBHS) has initiated a program of optional upgrades called “Fortified for Safer Living.” The partners include the National Network of Building Inspectors & Engineers, the Blue Sky Foundation and the Florida Alliance for Safe Homes.

These new homes are adapted to high winds, flooding and wildfires. The homes include peril-resistant criteria that go beyond the minimum requirements of local codes — from protection of all openings and a secondary moisture barrier on roofs to wind-resistant roofing and specified fasteners on thicker, plywood sheathing.

So far, five fortified homes have been built in the Tampa-St. Petersburg area.

“It is a prescriptive program,” says IBHS fortified program manager Chuck Vance. “There is nothing unusual about our program. It follows basic coastal regulations and Federal Emergency Management recommendations.”

If a hurricane strikes the Tampa-St. Petersburg area, the five fortified homes can be used as a comparison to existing homes, says Vance.

IBHS is extending the fortified program to North Carolina and other states.

“We are looking to work with builders and emergency management officials,” says Vance. “We chose North Carolina because it is a progressive state that has suffered from a lot of natural disasters and is ready for the program.”

Retrofitting Resources

When deciding on retrofitting options for your home, there are many available resources.

Clemson University and South Carolina Sea Grant researchers are designing a strong room that can be retrofitted into existing buildings. Soon, a detailed description about the new strong room will be published. Because the strong room does not meet a recently approved national standard for worst-case tornado storms, it is not cost-effective for new construction, according to Spencer Rogers, North Carolina Sea Grant’s coastal construction and erosion specialist.

If you want to install plywood storm shutters, researchers from South Carolina and North Carolina Sea Grant, Clemson and the Blue Sky Foundation have designed a new type of shutter that can be installed from the inside. The shutters must be prefitted. Use a ladder to install the permanent attachments for the shutters. Later this year, a brochure will be available on the new storm shutters.

For more information about retrofitting, contact Spencer Rogers, 910-962-2491, or rogerssp@uncwil.edu.

Following are some Web sites with retrofitting information:

- North Carolina Sea Grant, www.ncseagrant.org. Follow the extension links to coastal construction.

- South Carolina Sea Grant, www.scseagrant.org. Follow the links to extension and coastal hazards.

- Sea Grant’s HazNet, www.haznet.org.

- Clemson University’s Wind Load Test facility, www.ce.clemson.edu. Follow the links to research and structural geotechnical.

- Blue Sky Foundation, http://blueskyfoundation.org/.

- Institute for Business & Home Safety, www.ibhs.org.

To learn more about storm shutters, see “Hurricane Resistance: Retrofitting, Storm Shutters Increase Safety” in Coastwatch (Early Summer 2002).

This article was published in the Early Summer 2002 issue of Coastwatch.

For contact information and reprint requests, visit ncseagrant.ncsu.edu/coastwatch/contact/.