High-Pressure Processing Atlantic Blue Crab Meat

Using High-Pressure Processing (HPP) to extend the shelf life of fresh-picked, Atlantic blue crab meat

Background

The U.S. Atlantic blue crabmeat industry has significant culinary and economic importance in the United States – particularly in Louisiana, Maryland, North Carolina, and Virginia – where many small, independent crabmeat businesses operate. However, the industry faces multiple challenges such as limited shelf life and competition from imported crabmeat with a lower market price. The typical shelf life (or keeping quality) of fresh-picked blue crabmeat ranges from five to ten days. High-pressure processing (HPP) is a proven technology to extension the shelf life (keeping quality) of food and may help blue crabmeat processors expand their markets.

At the request of the Chesapeake Bay Seafood Industry Association, researchers at the University of Maryland Extension, in collaboration with the University of Maryland-Eastern Shore, Louisiana State University, NC State University, Virginia Tech, and Market Solutions investigated HPP technology on fresh-picked Atlantic blue crab meat. Th team developed an HPP process, confirmed the process delivers a shelf life of three weeks and conducted a cost analysis for processors to weigh the pros and cons of implementing HPP in their operations.

What Is HPP?

High-hydrostatic pressure processing or HPP is a non-thermal process where food is subjected to elevated pressures up to 600 Megapascal (MPa) or 87,000 pounds per square inch (PSI) or 6,000 atmospheres using water as the pressure transfer medium. The HPP technology can extend food products’ shelf life by damaging bacteria and viruses’ ability to thrive without the use of heat, chemical preservative or other food additives. Therefore, HPP can be considered as a green or eco-label technology, signifying to consumers that the technology to extend shelf life (or keeping quality) does not harm the crabmeat, or more broadly, the environment.

What Are the Advantages of HPP?

- Enhanced microbiological quality extends the shelf life (or keeping quality) of food

- Better microbiological quality reduces product losses due to spoilage.

- Better microbiological quality enhances the safety of food.

- HPP-treated food qualifies for green labels or eco-labels because the process only uses pressure as a means of preservation.

These benefits can boost the prime market advantage U.S. seafood producers have over their overseas competitors: many consumers prefer domestic seafood over imports when given a choice. Part of the market value U.S. seafood producers offer consumers is handling practices that protect the safety of seafood.

How Is Fresh Blue Crab Meat Treated by HPP?

- Fresh crabmeat is packed in plastic containers and is sealed with 10,000 oxygen-transmission-rate (10k) film.

- The prepacked crabmeat is introduced into a high-pressure vessel.

- The vessel is pressurized up to 600 MPa with water and is held at that pressure for 3 mins.

- The pressure is released.

- The food is unloaded from the vessel and the containers are packed in ice and then are placed immediately in a cooler for storage.

How Long Is the Shelf Life of Fresh and HPP Crab Meat?

Our studies show that HPP treatment significantly reduced the total number of bacteria on crabmeat, inactivated yeasts and molds, and delayed the growth of the remaining number of spoilage bacteria without appreciably affecting flavor, texture, aroma and appearance of the crabmeat. The HPP process achieved a shelf life (keeping quality) of three weeks while non-HPP-treated crabmeat lasted one week. HPP can extend the shelf life (or keeping quality) of fresh-picked blue crabmeat from one week to three weeks while retaining the desirable physicochemical, nutritional, and sensory attributes of untreated fresh-picked crab meat.

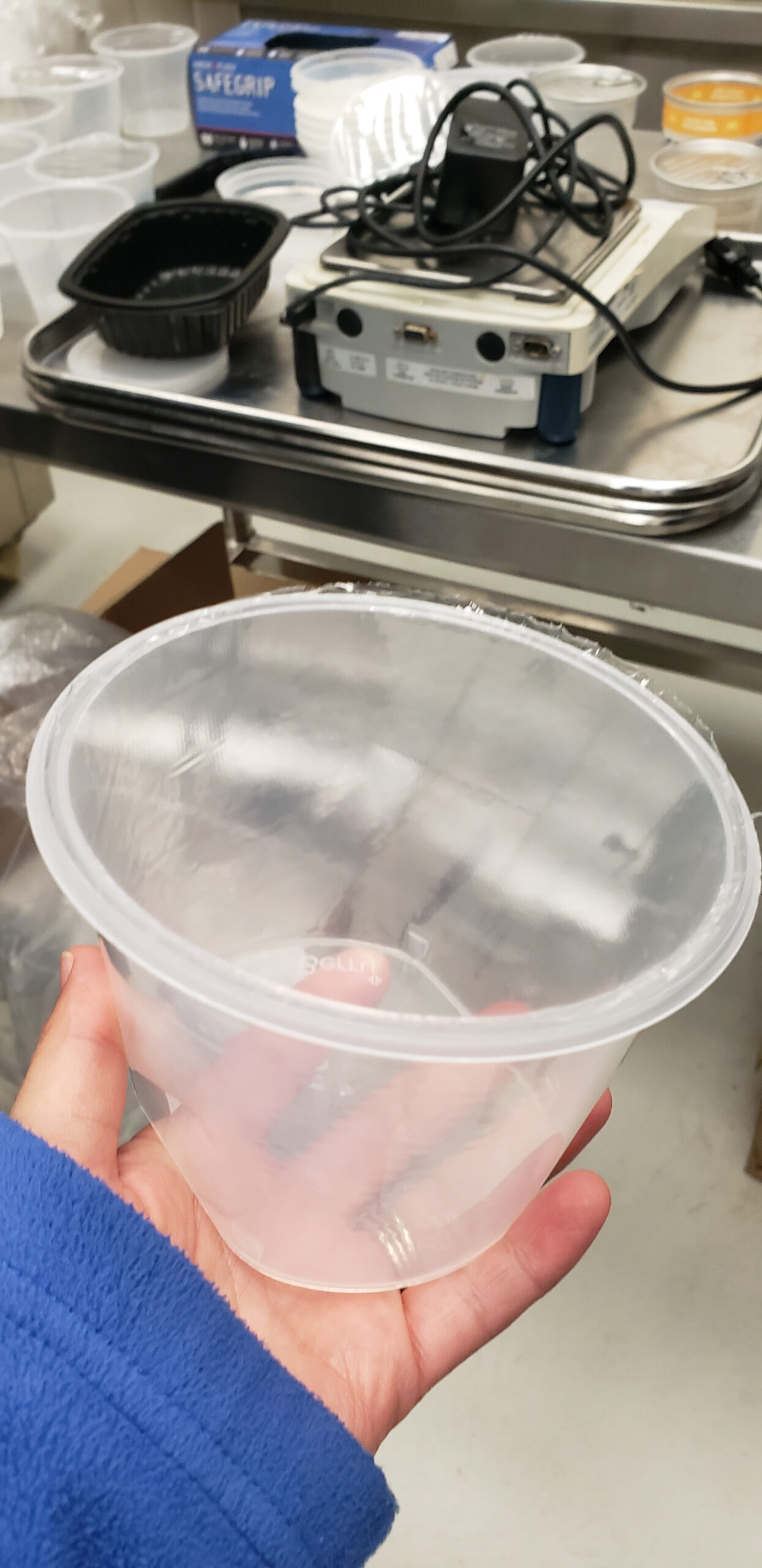

What Type of Packaging Material Can Be Used for HPP?

Our team used flexible packaging that can withstand the compression and decompression cycles during the HPP process. In the US, many blue crab processors use polypropylene (PP) cups to pack pre-cooked and freshly handpicked crab meat. Our studies show the PP cups widely used by the industry can withstand the high pressures of HPP. Four types of PP cups that we tested did not show dents, warps, perforations, or seal breakage after HPP treatment at 600 MPa for 3 min.

The containers must be water-resistant to prevent the water within the pressure chamber from getting into the product during the compression and decompression cycles. We recommend that the 10K OTR film should be used to seal the containers prior to HPP treatment. The 10K film is a plastic film that has an oxygen transmission rate of at least 10,000 cc/m2/24 h at 24C. It is a highly permeable film with water resistance and complies with U.S. Food and Drug Administration’s oxygen-permeability guidelines for packaging fresh seafood to prevent Clostridium botulinum Type E growth and toxin formation. If a 10k film seal is not available, an alternative approach may be applied as a water barrier to prevent water leaking into the package. For example, vacuum seal may be used prior to HPP treatment but the vacuum seal must be removed or broken to produce oxygen permeable environment after the HPP treatment for controlling the risk of Clostridium botulinum.

What Are the Drawbacks of HPP?

One drawback is that HPP does not eliminate all microorganisms, especially spores and viruses. Therefore, HPP cannot replace thermal processes for some foods, such as low-acid canned foods, and may require additional treatments or packaging methods to ensure safety and stability. Another drawback is the high cost of equipment and operation. HPP requires specialized machines that can generate up to 600 MPa of pressure and are expensive to buy and maintain. HPP also consumes a lot of energy and water and may need additional packaging materials.

What is the Added Cost of HPP Processing Crabmeat?

Domestic crabmeat processors could access HPP through a fee-for-service toll (i.e., a custom co-packer that has HPP capability) or by investing in equipment to do HPP equipment. The cost for a processor to do in-house HPP is estimated to be $1 million to $4 million depending on the size of the equipment. Toll processing would be approximately $0.50 to $1.00 per pound of meat and about $0.30 or less per pound with in-house equipment.

U.S. crab meat processors can access HPP technology either through a fee-for-service customer processor, such as Maryland Packaging of Halethorpe, MD or by investing in equipment and suppliers to HPP crab meat in-house. HPP equipment can be purchased from various companies, such as Hiperbaric High Pressure Technologies, Quintus Technologies, and others.

What Are Potential Economic Benefits of HPP for Domestic Blue Crab Meat Industry?

Based on extended shelf life (keeping quality) and a reduction in crabmeat losses due to spoilage, the potential benefits of HPP might be expected to include the following, based on an average wholesale value of $25 per pound for local crab meat (Source: Market Solutions LLC):

- Processor/Distributor loss reduction of 2.5% to 5% valued at $0.625 to $1.25 per pound.

- Foodservice and retail loss reduction of half of 20% valued at $2.50 per pound.

- Consumer loss reduction of half of 22% valued at $2.75 per pound.

Conclusion

High-pressure processing is an effective way to extend the shelf life of freshly picked blue crab by damaging spoilage microorganisms including bacteria, yeast and mold without changing the sensory and nutrition properties of products.

Reducing the added cost associated with HPP application in blue crab meat industry and other food industry is a continuing area of interest as different food products require different pressurization conditions and packaging technologies to work.

partners and collaborators

- Berry Global Group: Donated containers/lids

- Multivac: Donated 10K film

- Maryland Packaging and Quintus Technologies: Provided HPP service